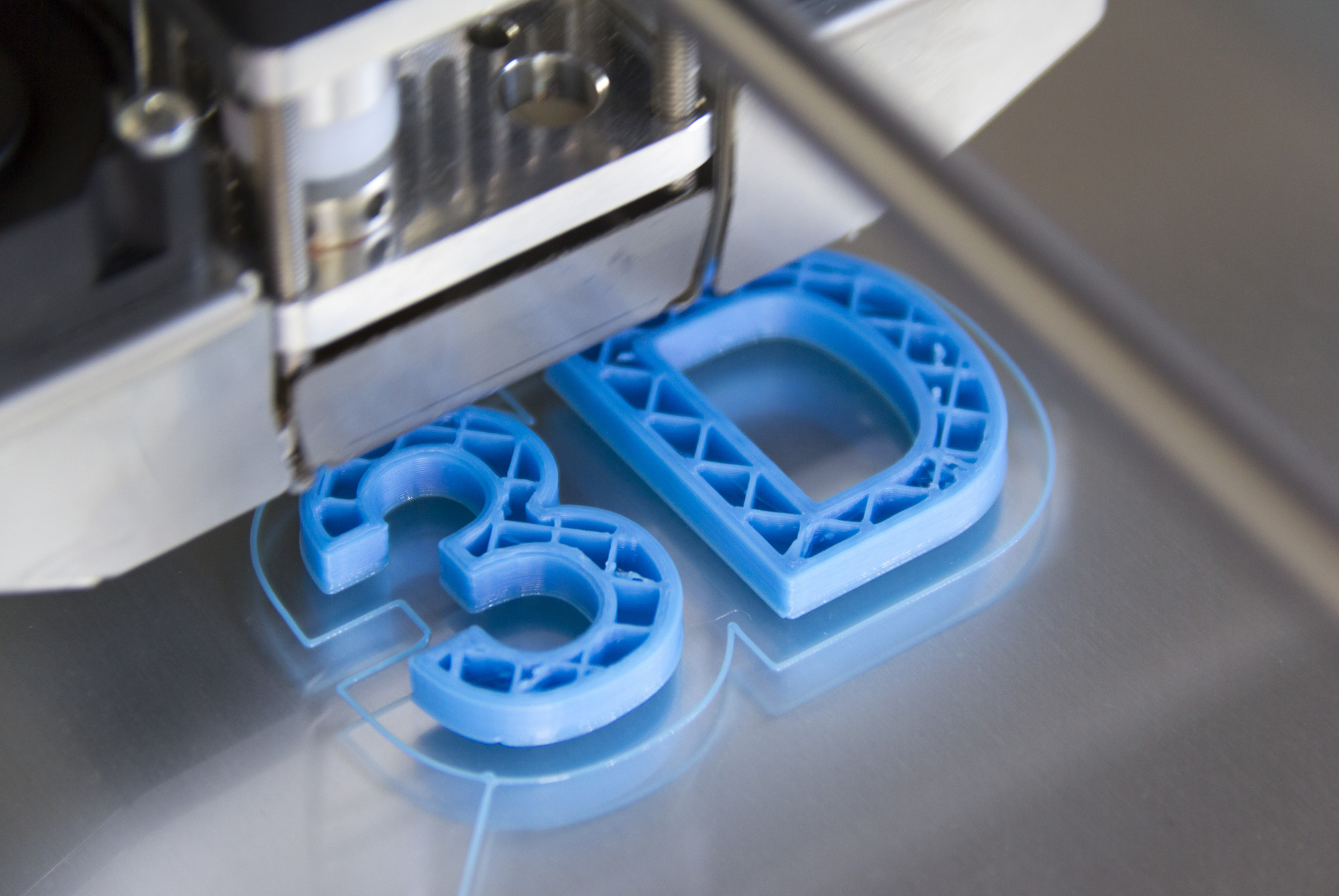

Imagine a world where you can be creative and explore your visions for new products before going into full production. 3D technology has found its way into the prototyping world and has made that world a reality.

You can use 3D prototyping services to test your product before going into full production. You can see how your product will look and how it will function. This could save you from making costly mistakes later in the production process.

We’re going to take a look at some of the biggest benefits of using 3D prototyping, so keep reading.

1. Hold, Feel, and See What Your Product Will Look Like

There is always an element of risk when going from prototype to production. 3D prototyping helps to negate some of this risk by giving you a physical version of your product to hold.

This can come in incredibly “handy” for products where it matters how it feels, whether it’s a handheld item or something like a chair.

It’s far easier to pick up on any issues compared to looking at a 3D model on a screen.

2. 3D Prototyping Is Fast

You’d be forgiven for thinking that getting a 3D physical prototype of your product is something that you have to wait a long time for. Before the days of 3D printing, it was!

Rapid prototyping services are becoming more popular (see https://www.rapidpsi.com/prototyping/) for an example.

Fast service, in some cases, means compromising on quality. Rapid prototyping is quite the opposite, producing high-quality prototypes at a rapid pace.

3. Let Prospective Customers Feel the Product

A 3D physical prototype of a product is an excellent sales asset. Imagine, rather than having to sell using verbal descriptions and diagrams, you could hand someone a functioning prototype of the product.

It will speak for itself, making your sales and marketing efforts a breeze!

4. Testing Prototypes Saves on Cost

Traditional prototyping is a longer, and often expensive process. A huge benefit of rapid prototyping is that you can test your prototypes without fear of incurring huge costs if you need to tweak or change anything.

You could even produce several of the same prototypes in a far shorter space of time than using traditional prototyping methods.

5. Rapid Prototyping Produces Less Waste

Traditionally, when you build a prototype, you’d use a “subtractive process,” meaning you start with the materials you have, and use what you need. The rest, while potentially reusable, can be classed as waste.

With complete prototype services using 3D printing, the process is called additive manufacturing, where there is no wastage because the technician will only use what they need.

Prototyping Services Are Changing the Process of Production

Rapid prototyping services take the guesswork out of creating products that sell. This is a real game-changer because it can save time through faster production, testing, and reproduction.

If you’ve enjoyed this article or found it useful, check out more like it on our blog.