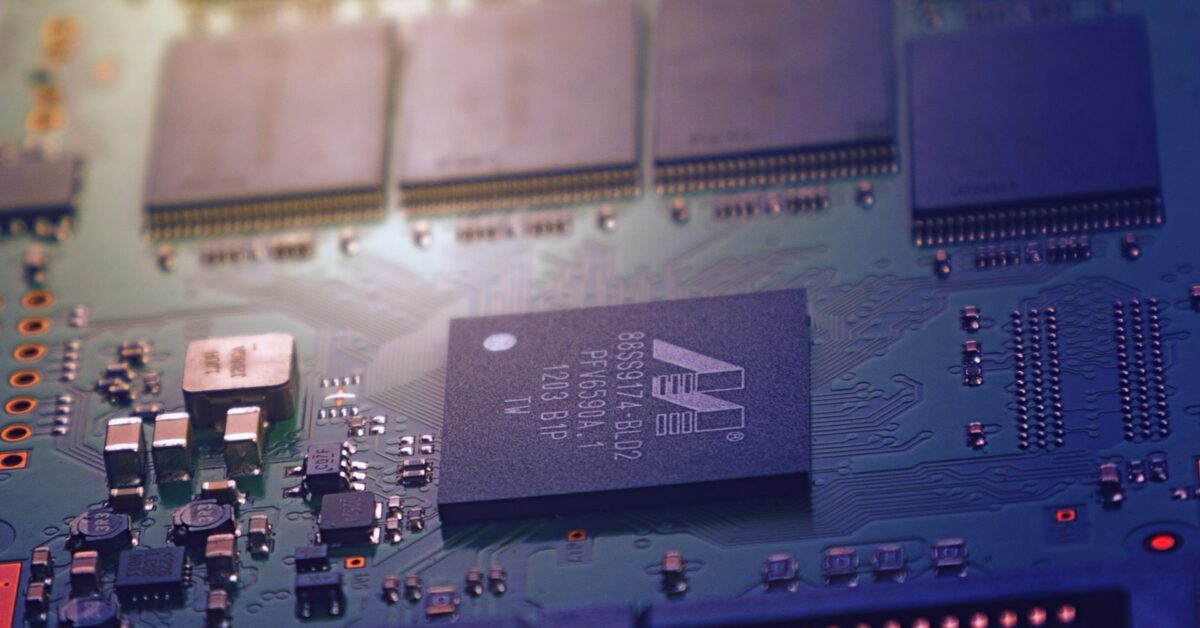

From the bustling cities of Sydney and Melbourne to the vast outback of Australia, printed circuit boards (PCBs) are the silent force propelling your modern world forward. These intricate electronic components are the backbone of virtually all electronic devices, from smartphones to advanced medical equipment.

While many consumers may not be familiar with PCBs, their suppliers play a pivotal role in driving tech innovation behind the scenes, even in the unique context of Australia’s technological landscape.

With Australia’s burgeoning tech scene, from startups in Melbourne’s vibrant innovation hubs to research institutions in Brisbane and Perth, PCB suppliers are integral to fostering innovation across the continent. This article will delve into the world of PCB in Australia to uncover their critical role in shaping Australia’s technological advancements.

Contents

Driving Miniaturisation: The Role of Advanced Manufacturing

One of the most significant trends in electronics is miniaturisation, where devices are becoming smaller and more powerful. This trend places immense pressure on PCB manufacturers to create boards that are not only smaller but also capable of handling increased power and complexity. Advanced manufacturing techniques, such as surface mount technology (SMT) and multilayer PCBs, have been game-changers.

SMT enables components to be mounted directly onto the board’s surface, eliminating the need for bulky leads and making it possible to pack more components into a smaller space. As the name suggests, multilayer PCBs have multiple conductive material layers separated by insulating layers. This design vastly increases the board’s complexity and density, enabling more functionality in a smaller form factor.

Innovating for Performance: High-Speed PCB Design

High-speed PCB design has become crucial as your devices demand faster and more efficient performance. From data centres to 5G networks, the need for high-speed data transmission is driving innovation in PCBs. Suppliers are developing boards with carefully controlled impedance, minimising signal loss and ensuring data integrity even at incredibly high speeds.

These high-speed designs require meticulous planning and precision manufacturing.

Components must be placed and routed with extreme care to avoid signal interference and crosstalk. PCB suppliers are investing in cutting-edge design software and manufacturing equipment to meet these demanding requirements.

Enabling Next-Generation Technologies: Flexible and Rigid-Flex PCBs

Another area where PCB suppliers drive innovation is flexible and rigid-flex PCBs. These types of boards are revolutionising industries such as wearables, medical devices, and aerospace. As the name suggests, flexible PCBs can bend and conform to various shapes, making them ideal for applications where space is limited or the board needs to flex during use.

Rigid-flex PCBs combine the benefits of rigid and flexible boards, allowing for complex three-dimensional designs. These boards are finding their way into foldable smartphones, smart clothing, and even implantable medical devices. Suppliers constantly push the boundaries of materials science and manufacturing techniques to create these next-generation PCBs.

Sustainability and Green Technology

Besides pushing the boundaries of performance and flexibility, PCB suppliers also focus on sustainability and green technology. The electronics industry generates a significant amount of waste, much of it from discarded PCBs. Suppliers are working on recyclable materials and processes to minimise this environmental impact.

Furthermore, energy efficiency is a growing concern, with devices needing to be more power-efficient. PCB suppliers are developing designs that reduce power consumption without compromising performance. This focus on sustainability benefits the environment and aligns with the growing demand for eco-friendly items.

In conclusion, as the world marvels at the latest smartphones, smartwatches, and other cutting-edge devices, it’s important to recognise the unsung heroes behind their innovations. Suppliers of PCB in Australia are the driving force behind the scenes, pushing the boundaries of what’s possible in electronics. These suppliers are at the forefront of tech innovation, from advanced manufacturing techniques to high-speed designs and next-generation materials.

Their commitment to innovation, performance, and sustainability ensures that the gadgets you can’t live without continue to advance and improve. So, the next time you hold a sleek smartphone or marvel at a futuristic medical device, remember that behind its sleek exterior lies a world of intricate PCBs driving tomorrow’s technology.